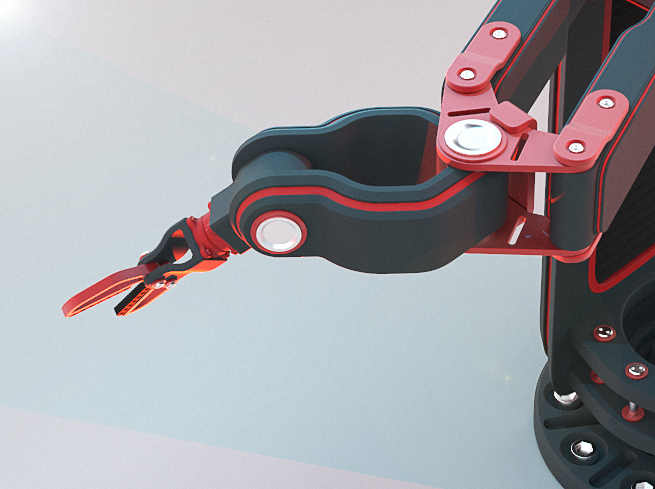

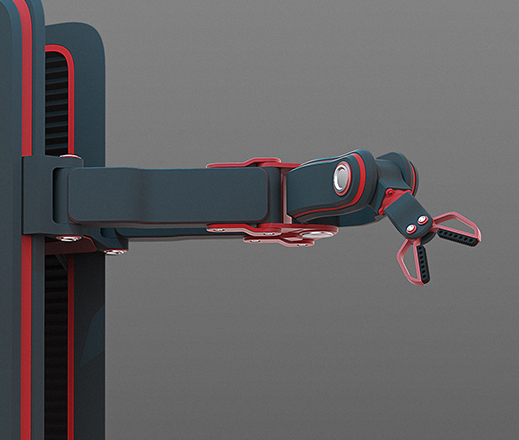

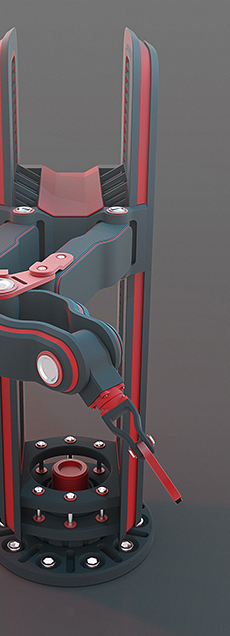

Reducing risk and human factors. Increased accuracy and repeatability of operations performed. Reducing the marriage of manufactured products. 100% control over the work of the production cell without downtime and errors

The installation of robots increases labor efficiency and profitability of production. When working in three shifts, taking into account the cost of salary, taxes and additional costs when using manual human labor and hiring employees.

The possibility of reliable operation 24/7 in any conditions. The temperature in the shop from -30 to +40 °С. Harmful and hazardous production. It is not required to comply with labor protection regulations intended for humans

We train customer employees to set up and maintain the robot for free. Any worker after a 5-day training course is able to reprogram the robot to perform new operations.