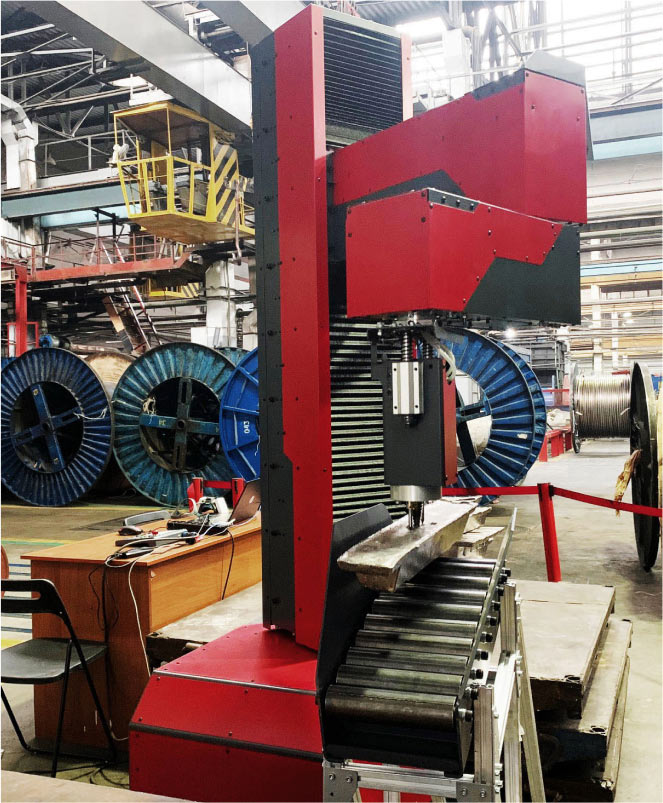

"MOSKABELMET"

Supply and commissioning of the Aripix A1 robotic hardware-software complex

For the plant were delivered:

- Robotic arm

- Computer vision system

- Complex control panel

- Spare parts and quick wear elements for normal operation during the warranty period

- Manual

Work cycle: using machine vision, the robot determines the exact position of the ingot, uses special grip and transfers it to the place of release into the furnace. The robot will replace 4 employees performing harmful work. The power of the robot allows you to move up to 50 tons of metal per day, which greatly exceeds human capabilities.

The installation of the robot allowed the enterprise:

- Upgrade production

- Eliminate human errors and downtime

- Increase productivity

- Reduce payroll costs

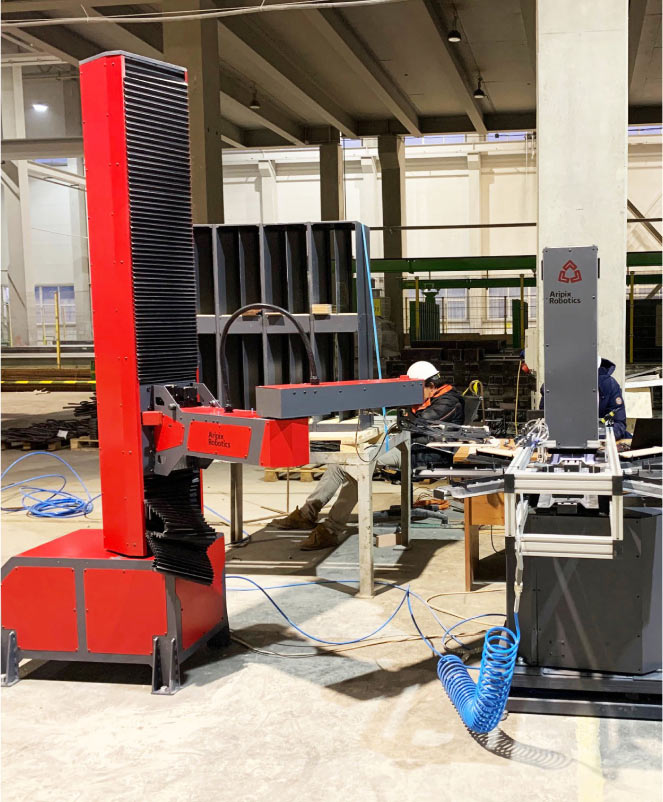

Supply and commissioning of the Aripix A1 robotic firmware

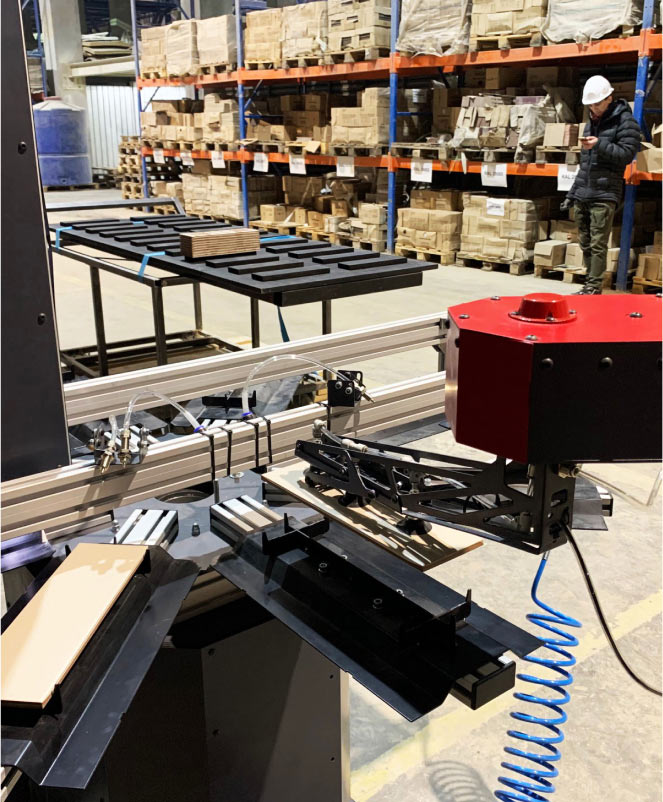

Tasks solved by installing Aripix A1 robots:

- sorting ceramic tiles with different colors into special stores;

- inspection of defects and tile geometry before being placed in the store;

- rejection of tiles that have not passed the control of color and geometry;

- reception through the external interface from the customer software of the color scheme of tile laying.

The composition of the complex:

- tiled shelving

- robotic arm designed to move tiles from the feeder rack to the area of operation of the computer vision system

- robotic arm designed to move tiles that have passed color and shape control onto a pallet

- computer vision system that allows sorting by color, shape and presence / absence of marriage

- tile transport

- rejected tile insulator

- sorted tile tray

- complex management controller

- user's manual

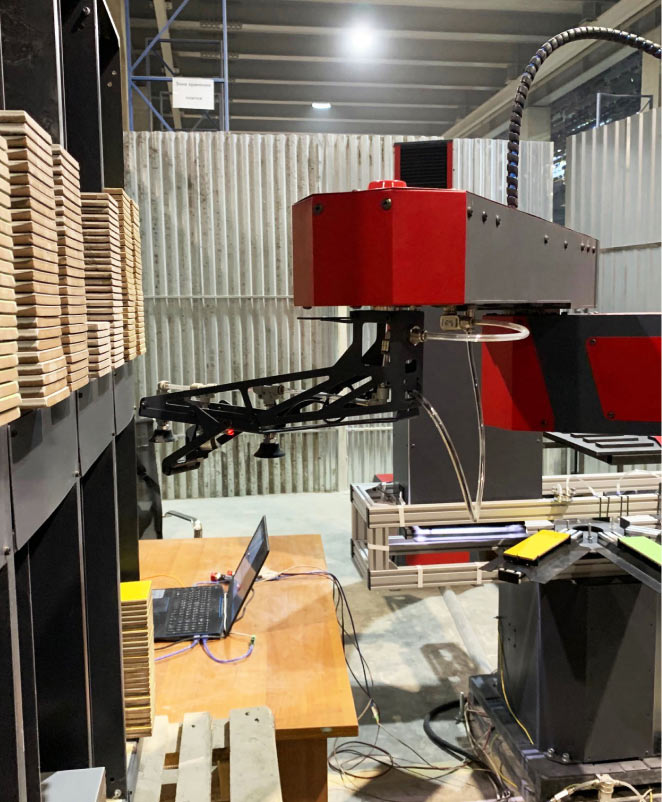

Robots replaced 8 workers, which were transferred to other areas. The complex receives the task of the layout of the customer’s IT system. The first robot picks up the tile of the desired color from the cell of the feeder rack and puts it on a rotating table. On the table, the tile is photographed and checked for scratches, the correct color and size of the tile.

As a result of installing robots:

- there was a computer vision system for controlling tiles

- the number of defective boards has been reduced

- downtime reduced, production cycle increased

- payroll costs reduced

- improved production quality